The wood for our foldable box

The main material of the FridayBOX is plywood, often also called multiplex – a fantastic material for our foldable boxes that can be made from different types of trees.

But not every type of plywood is suitable for the FridayBOX: poplar, for example, is too splintery and beech panels are often badly warped. We therefore manufacture the FridayBOX from shiny, mostly light-colored European birch. This is a great wood, also concerning the technical features.

Wood & Linseed Oil

A tough duo from nature.

The FridayBOX is treated with linseed oil. Linseed oil is used to protect wood for centuries. It is absorbed deep into the wood and hardenes over time. The wood structure stays ‘open’ but is protected from moisture anyhow. We add a bit of orange oil, that accelerates the drying.

This protection can be reinforced or renewed by anyone if necessary. Just put a bit of linseed oil on a cotton tissue and add a thin layer of oil to the FridayBOX.

Technical data in detail

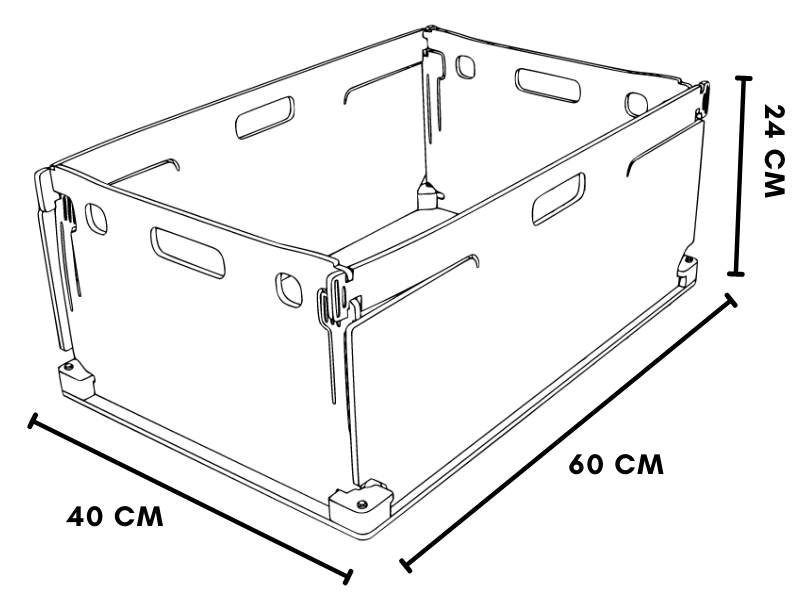

The BIG one

external dimensions

Folded open 400 x 600 x 245 mm, height in stack 241 mm

Folded flat

400 x 600 x 33 mm

Height in stack 29 mm

Internal dimensions

370 x 558 x 235 mm

Weight 3kg +/- 0,2kg

Volume ca. 48 litre

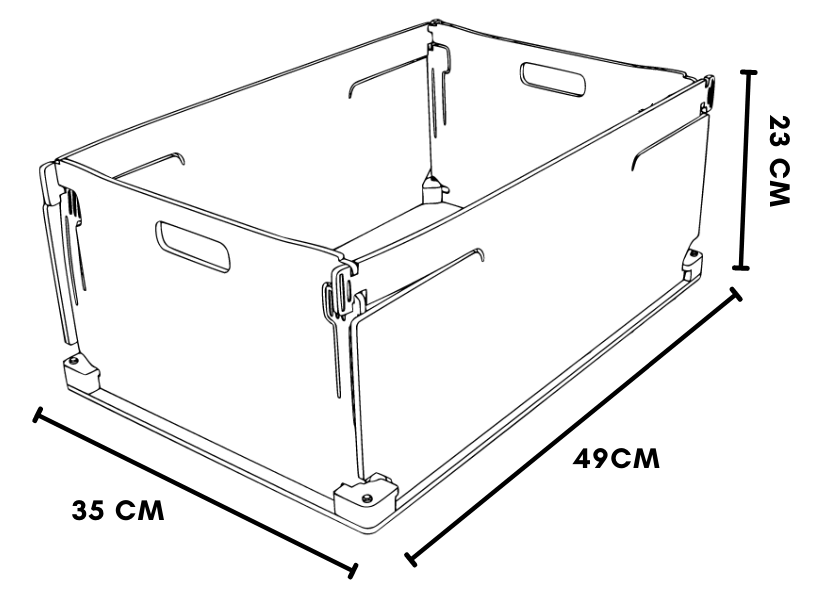

The SMALL one

external dimensions

Folded open 350 x 490 x 235 mm, height in stack 231 mm

Folded flat

350 x 490 x 33 mm

Height in stack 29 mm

Internal dimensions

320 x 448 x 225 mm

Weight 2,3kg +/- 0,2k

Volume ca. 32 litre

Here is a picture to compare the size of erected wooden boxes and a big box that is folded together to a height of 33 mm.

A lower version of the big FridayBOX is planned. If you are interested please reach out ot Michael info@friday-box.com.

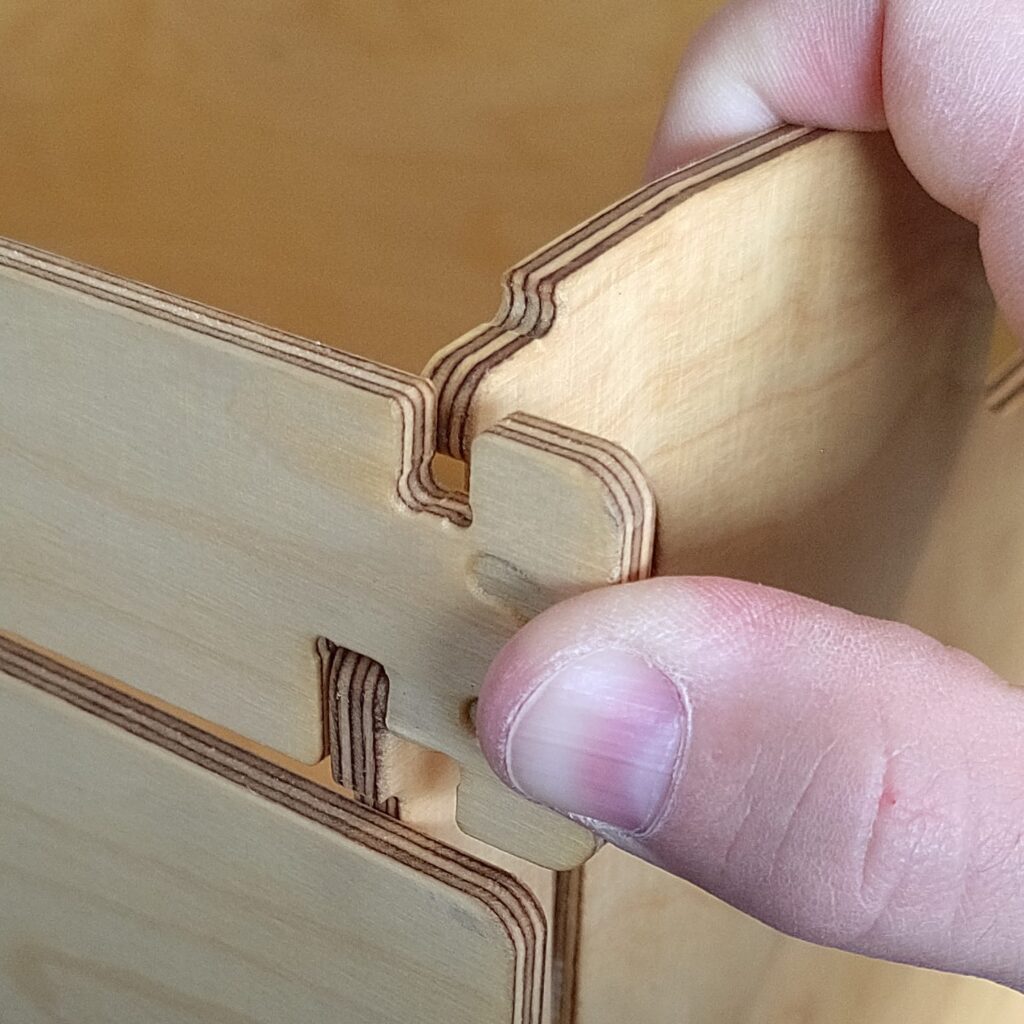

Fastening of the foldable box

The fastening of our foldable wooden box relies on the flexibility of the wood and the proper incisions and geometries, that enables our mechanism withour further fittings or binders.

On all four upper corners the mechanism can be easily and quickly snapped into place.

Folding the box is equally quick. Once the fastening is unlocked, the sides fold smoothly together – nearly by themselves.

How high is the folded FridayBOX?

Folded together the FridayBOX is like a hint of nothing: the big one as well as the small one is only 33 mm thin. By being so slim the FridayBOX can be stacked perfectly and particularly space saving when you don’t need it right know. But who owns the box will realize quickly: basically it is nearly never not in use.

How strong is the FridayBOX?

Laboratory and practical tests show that the FridayBOX is a very robust folding box. The wood is not sensitive to heat and cold as it gets neither brittle nor rough under those exposure. In addition to that our box can be heavily loaded!

Meanwhile there are more than 1000 FridayBOXes out there in urban and rural wilderness showing customers and us successfully how robust the box is.

One thing we already know for sure:

The FridayBOX can hold more weight than most of us are able to carry. And sitting on it is more an issue of space as our robust foldable box can support more people than those who can sit on it even when sitting on top of each other.

Where is the FridayBOX manufactured?

Home of the FridayBOX is the Rhineland – between Cologne and Dusseldorf. In the Projekt-Zentrale in Dormagen the FridayBOX was invented and continually developed further. Here Michael and the team manufactured the first batches until end of 2022.

Since January 2023 the FridayBOX is manufactured at the Varius Werkstätten run by the Lebenshilfe Rhein-Kreis-Neuss. Michael worked with the Varius team in Grevenbroich for several weeks to get the production started. It took some time to train the colleagues on how to use the CNC machine and manage the technology and software that comes with it. And also to teach them all the tricks and learning a lot himself.